Food Irradiation

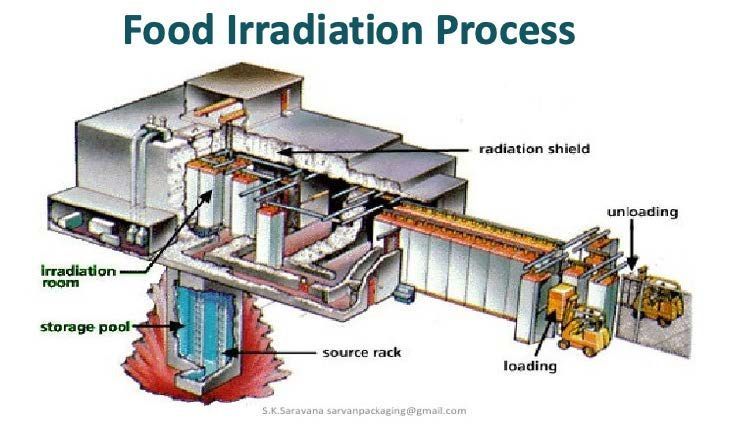

Food Irradiation (the application of ionizing radiation to food) is a technology that improves the safety and extends the shelf life of foods by reducing or eliminating microorganisms and insects.

There are three sources of radiation approved for use on foods Gamma rays, X-rays, and Electron beams. Francisco Diez-Gonzalez, Food Safety Director at the University of Georgia Center, said “Irradiation has proven it can reduce the count of salmonella and listeria by more than 99.99 percent. It’s capable of killing viruses. Irradiation also helps to reduce microorganisms that could have an influence in spoilage.”

What does Irradiation do to plastics, rubber, and urethane? Some polymer materials can degrade due to overexposure to radiation sources including protons (alpha), electrons (beta), and photons (gamma, X-rays). This degradation can lead to efficiency lost, down time, and increased power consumption.

Physical properties of polymers can be impacted with repeat exposure to radiation. These impacts are not always visible or understood. For example, a critical component such as a gear may experience a decrease in shear strength or tribological properties. Surface degradation, discoloring, or material shedding are common visual signs that a component is being affected by radiation. The risk of component failure increases with multiple exposure to radiation cycles. Choosing the right material upfront limits conveyor down time.