Plastics Role In Meeting The Ever Increasing Global Food Demand

Food automation equipment is ripe for disruption.

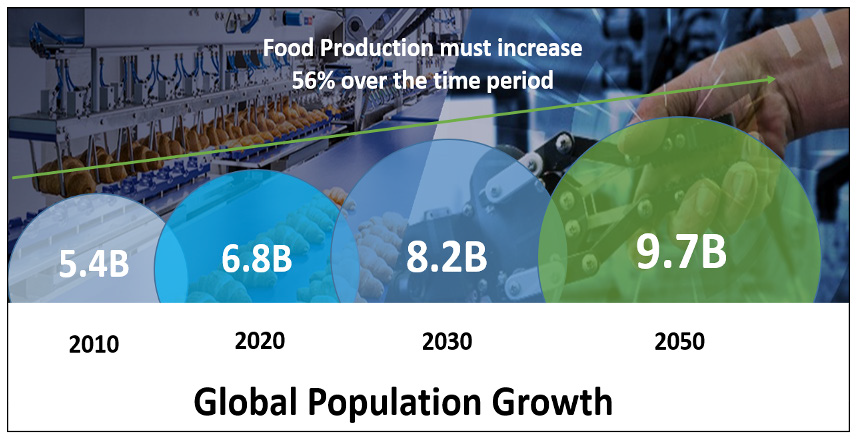

The Food Processing and Handling sector is a critical factor in providing the systems, machinery, and equipment that enable the food industry to feed the global population. With the current global population nearing 8 Billion and expected to reach 10 Billion by 2050, we must increase food production by nearly 60% to adequately feed the world. Think about that; significant innovations will be required to keep up with demand. Plastics will need to play a role in this efficiency gain.

Expectations

Changes in consumer expectations and rapid AI technology transformation are key catalysts for disruption. Increased investments in food automation technology will provide tremendous growth opportunities for plastic consumable parts.

Food Processors will require plastic components that link to Artificial Intelligence, notifying engineers when a part is ready for replacement. These parts can increase efficiency and have the ability to help control the process by being key analytical communication links.

So, What’s Next For Plastics?

The Food Industry will experience an array of new technologies, materials, and food regulations. Polymer manufacturers are actively looking to integrate innovative new technologies into what are today’s traditional polymer solutions. Food Processors desire consumable components integrated directly into the automation software system. This provides huge savings in terms of cost and efficiency as PM cycles are optimized. The challenges are certainly there for the plastics industry to provide the innovation required so that the Food Equipment Industry can stay ahead of the growth curve in feeding the global community.