The Effects Of Friction On Food Processing

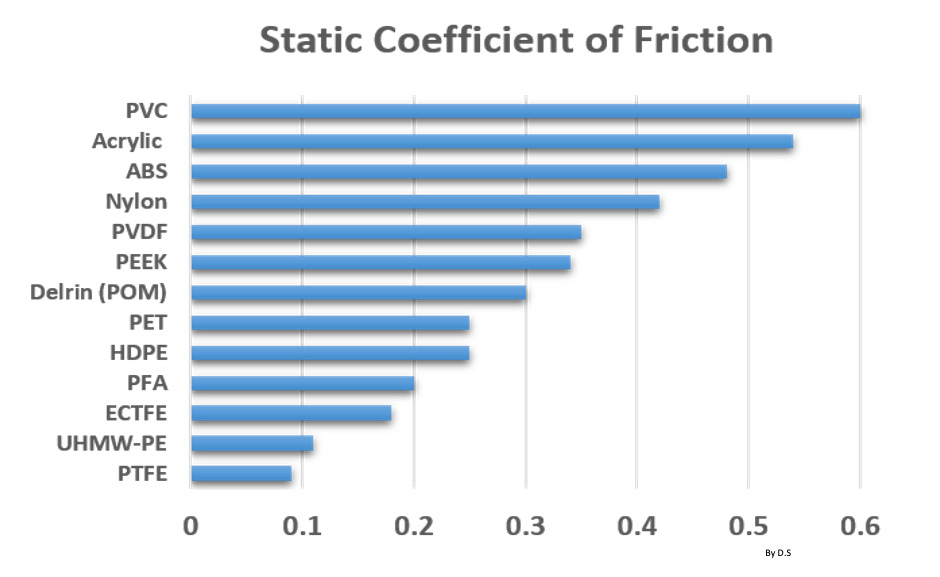

FRICTION is a common force that significantly affects the motion of moving objects in a system. Reducing Friction with respect to Food Automation Equipment is a challenge that engineers are constantly faced with. So how do you determine what is the optimum sliding material for your application? To answer this we first define the two types of friction, Static and Dynamic.

Static Friction

Is a force that when applied keeps an object at rest. This means servo motors that drive Food processing equipment must overcome static friction to be automated. Materials with high Static friction require larger servo motors and consume more power.

Dynamic Friction

Is defined as a force acting between two moving surfaces: In food processing equipment this creates frictional heat, surface wear, and static build up. Static and Dynamic friction decrease in performance as temperature increases. This results in the slowing of a moving systems. Engineering plastics minimize frictional forces resulting in faster line speeds and a decrease in power consumption. When choosing a plastic it’s important to understand effects of localized frictional heat, environment temperature, and the materials CoF at operating temperature. Laird Plastics is the one source to bring together the wide range of critical physical properties needed enabling engineers to make optimal material choices and design decisions for their applications. Understanding a few key properties can deliver enhanced performance, increase line speeds, reduce power consumption, and lower maintenance cost.

Three Common Materials Used In Food Processing

UHMW-PE: COF .12 - .20 static with excellent abrasion properties. Excels in cold environments less than 40deg F. UHMW is chemically inert and has zero moisture absorption which minimizes bacteria growth. Very close to PTFE but has better compressive strength over PTFE.

NYLON: COF >.5 static Excels in dry environment, excellent wear properties, and extremely tough especially where shock loading or impact is present.

ACETAL: COF >.25 static. Excels in a wet environment, good Compressive strength and improved dimensional stability.